Yield stress formula for steel 325625-Yield stress formula for steel

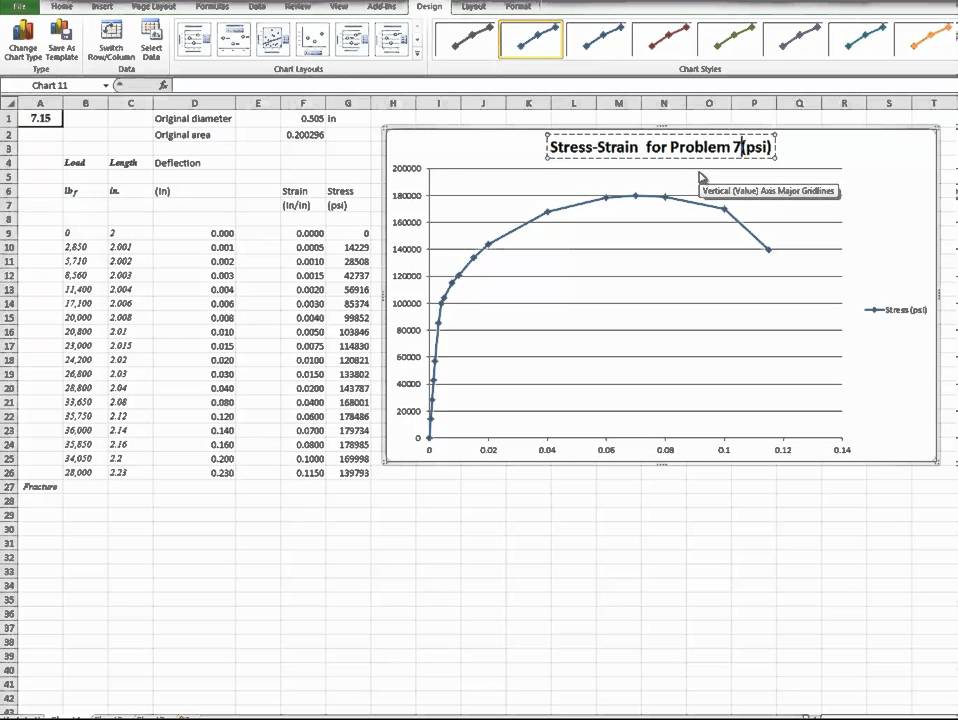

F b = The computed stress in the beam in bending M = The maximum moment acting on the beam Z x = The Plastic Section Modulus in the x or strong axis Z x is similar to the Section Modulus of a member (it is usually a minimum of 10% greater than the Section Modulus) (in 3) F b = The allowable stress of the beam in bending F y = The Yield Strength of the Steel (eg 36 ksi, 46 ksi, 50 ksi)Allowable Stress (Strength) The allowable stress or allowable strength is the maximum stress (tensile, compressive or bending) that is allowed to be applied on a structural material The allowable stresses are generally defined by building codes, and for steel, and aluminum is a fraction of their yield stress (strength)Similarities between yield strength and ultimate strength For highly brittle materials, yield strength and ultimate strength are also same (plastic deformation of brittle materials is negligible) Both are basically measurement of stress Both are measured in same unit (N/mm 2)

The Uniaxial Yield Stress For A Steel Material Is Chegg Com

Yield stress formula for steel

Yield stress formula for steel-Fatigue limit, endurance limit, and fatigue strength are used to describe the amplitude (or range) of cyclic stress that can be applied to the material without causing fatigue failure;Hari om, you are asking a question as to " What is the allowable stress for mild steel?" Hari om Hari om ANSWER The allowable strength or allowable stress is the maximum stress (tensile, compressive or bending) that is allowed to be applied

Q Tbn And9gcrdlwvzddnehsqd3q4pa68yhsrtz2zujhc4jj P3hg9jteevyia Usqp Cau

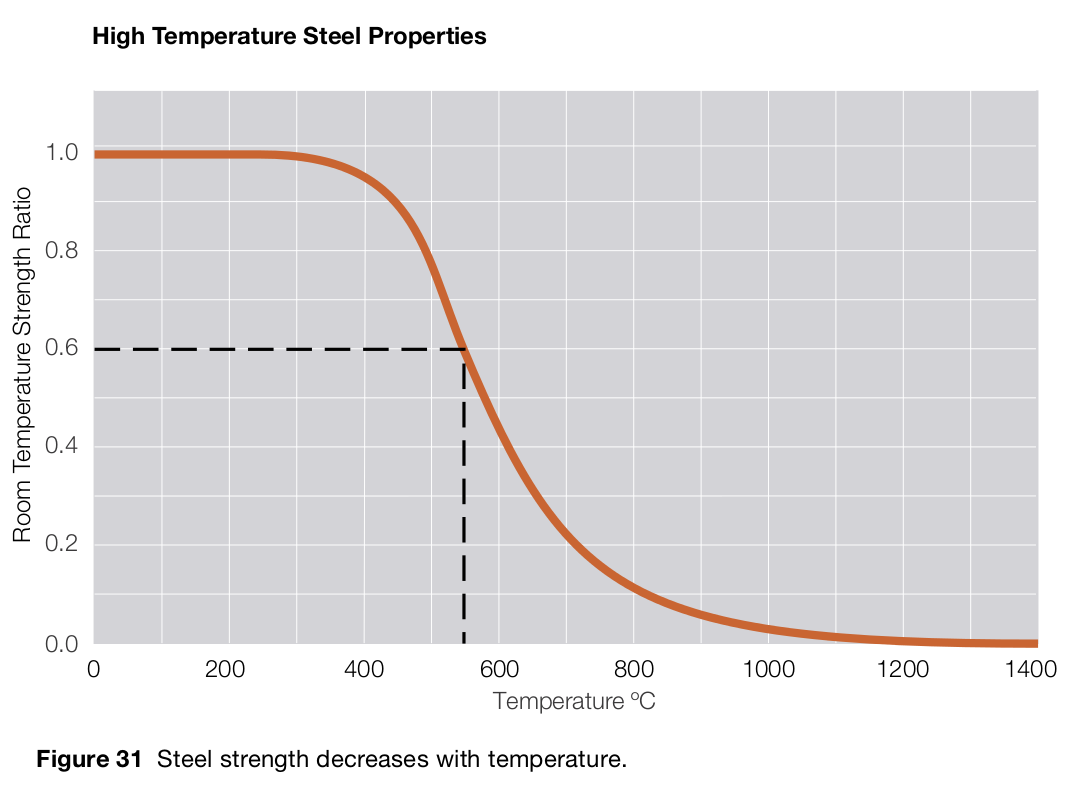

Alloys like steel, which are created by feeding iron various species of impurities, are the best examples of such manipulation Another way to achieve a greater yield stress is to manipulate the material at lower temperatures Higher temperatures add to the stress, as thermal energy causes the atoms to vigorously jiggle and displaceThe true stress and true strain are defined below For accurate calculations, the true stresstrue strain curve for the metal should be drawn to determine the yield strength Figure 16 redrawn on true stresstrue strain axes would look like the one shown in Fig 18Yield moment M Y If the stress due to applied moment is at or below the yield, the stress distribution is linear Max moment for which the stress is linearly varying is the yield moment M Y C=T =(bh/2)(σ y/2) M Y=C*(lever arm)=C*(2h/3)=(bh2/6)σ y =Sσ y Elastic section modulus for rectangle, S=(bh2/6) Section modulus is listed for other sections

F FORCE SECTION AREA = STRESS= 30 000 N mm X mm STRESS= 30 000 400mm STRESS=The working stress or allowable stress is the maximum safe stress a material may carry The working stress should not exceed proportional limit Since the proportional limit is difficult to determine accurately, we take yield point or the ultimate strength and divide this stress by a suitable number N, called the factor of safetyMaterial 1045 Steel, Yield Strength= 530 MPa, Ultimate Strength= 625MPa Max Stress o The shaft is keyed for a 1/8" key, thus the actual yield strength can be equated to ¾ the materials yield strength (Keyed Yield Strength=398 MPa) o Loading is comprised of three components MomentBased on the axle length between bearings and radial load

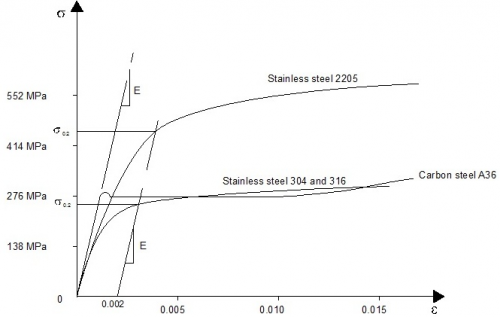

This assumes that yield occurs when the shear stress exceeds the shear yield strength τ = σ 1 − σ 3 2 ≤ τ y {\displaystyle \tau ={\frac {\sigma _{1}\sigma _{3}}{2}}\leq \tau _{y}\,\!} Total strain energy theory – This theory assumes that the stored energy associated with elastic deformation at the point of yield is independent of the specific stress tensorYield Strength is the stress a material can withstand without permanent deformation or a point at which it will no longer return to its original dimensions (by 02% in length) Whereas, Tensile Strength is the maximum stress (usually represented in PSI) that a material can withstand while being stretched or pulled before failing or breakingThe stressstrain diagram for a steel rod is shown and can be described by the equation ε=0(1e06)σ0(1e12)σ 3 where s in kPa Determine the yield strength assuming a 05% offset

What Is Proof Stress Civildigital

How To Find Yield Strength Quora

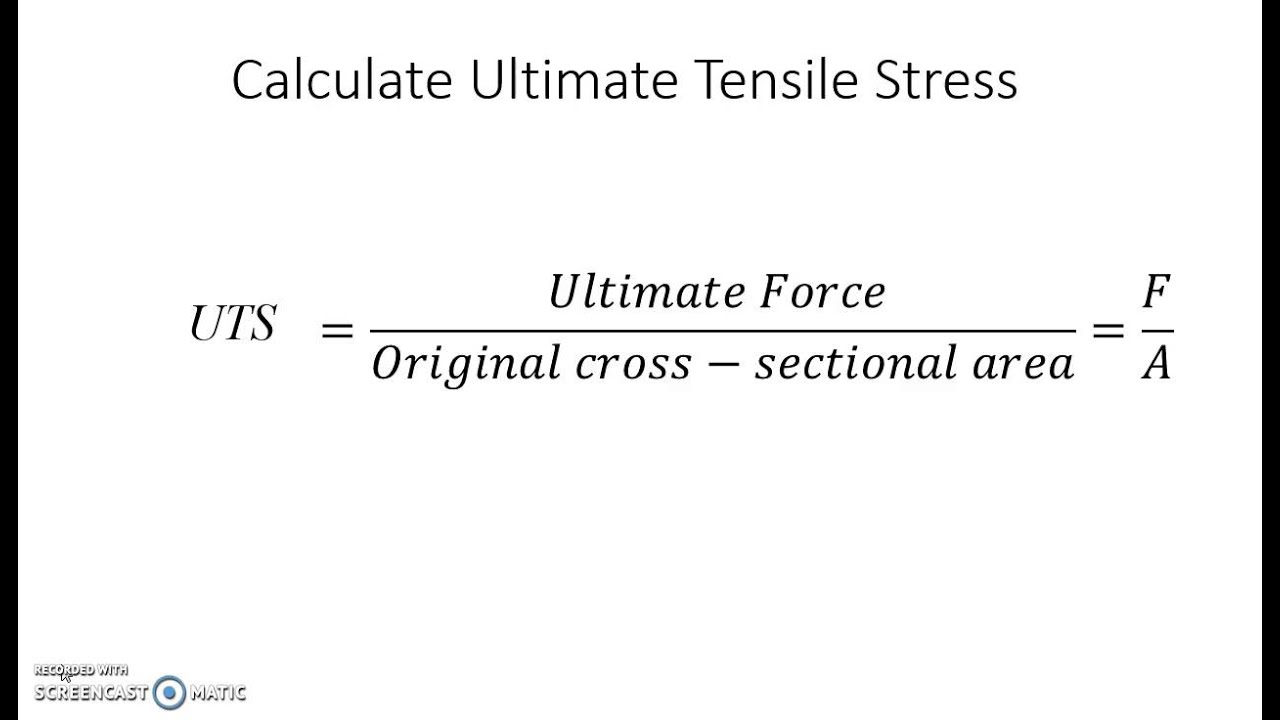

Yield strengths vary from 35 MPa for a lowstrength aluminum to greater than 1400 MPa for very highstrength steels In many situations, the yield strength is used to identify the allowable stress to which a material can be subjectedYIELD STRESS MATHEMATIC APPLICATION F/A FORCE AREA = STRESS= FORMULA 1 A sample of steel ( from an engineering company) is given a stress test to assess its yield stress The steel is a mm square section The sample begins to yield at 30 000 Newtons What is the yield stress?Meaning you basically calculate this out using the formulas in the manual for axial (), moment (), or shear without applying the resistance factor or safety factor (more on this below) ASD From the nominal capacity, if you divide it by Ω, you end up with the allowable strength (eg

Yield Strength Strength Mechanics Of Materials Engineers Edge

Yield Strength Yield Point Stress Strain Curve

Context, the term 'High Strength Steel' (HSS) is used for those steels of yield stress 450 MPa and above One of the principal obstacles to the increased use of such steels is the severe restrictions placed on them in design codes;Yield stress Thus (2) 2 2 λ EI Pcr π = represents the maximum load that the strut can usefully support It is often convenient to study the onset of elastic buckling in terms of the mean applied compressive stress (rather than the force) The mean compressive stress at buckling,σcr, is given by 2 2 Aλ EI A Pcr cr π σ = =Compressive stress stress that tends to compress or shorten the material acts normal to the stressed area;

Steel Material Properties Steelconstruction Info

What Is 0 2 Proof Stress Of Steel Quora

Type the value in the box next to Mpa (using the drop down to change the unit of measurement) ksi MPa N/mm² psi = ksi MPa N/mm² psi Use the following calculator to convert Izod or Charpy values from Joules (J) to foot/pound (ft/lbs) or vice versaThe 02 Percent Offset Rule The most common engineering approximation for yield stress is the 02 percent offset rule To apply this rule, assume that yield strain is 02 percent, and multiply by Young's Modulus for your material σ = 0 0 0 2 × E \sigma = 0002\times E σ = 0002×EThe bending moment that it takes to yield that section equals the section modulus times the yield strength In simple terms, the section modulus is the ratio of bending moment to bending stress for steel If your steel has a high section modulus it will be harder to bend and can withstand a high moment without having high bending stress

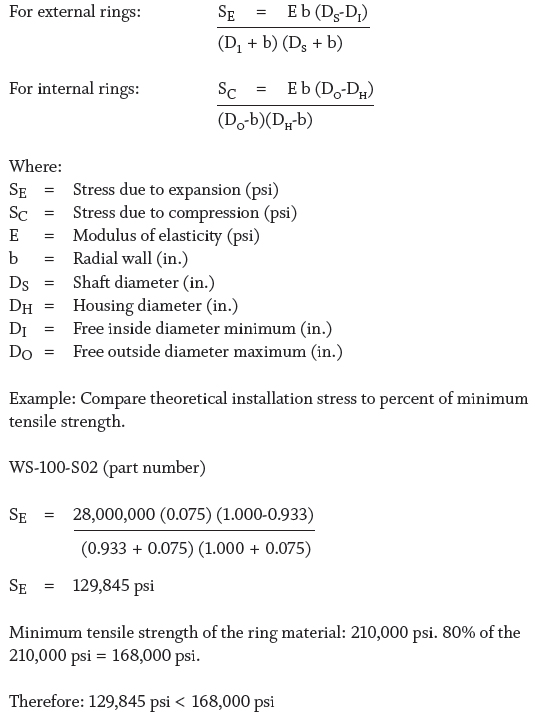

Careful Calculations Affect Ring Design

.jpg)

Yield Stress Calculation Methods

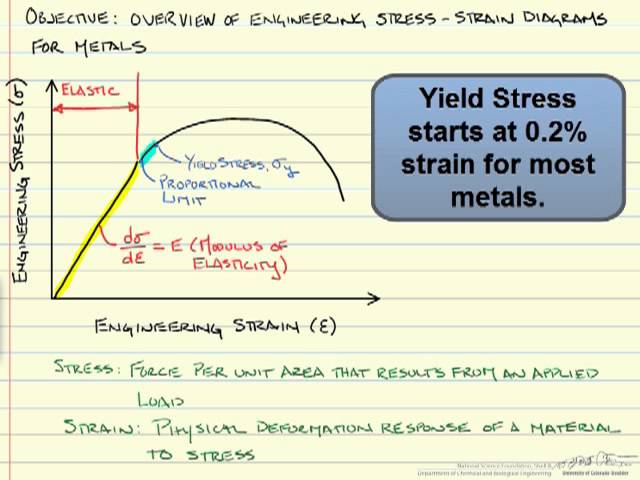

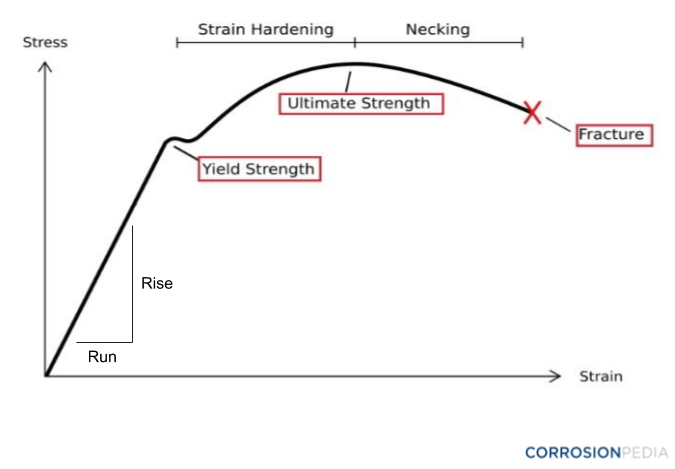

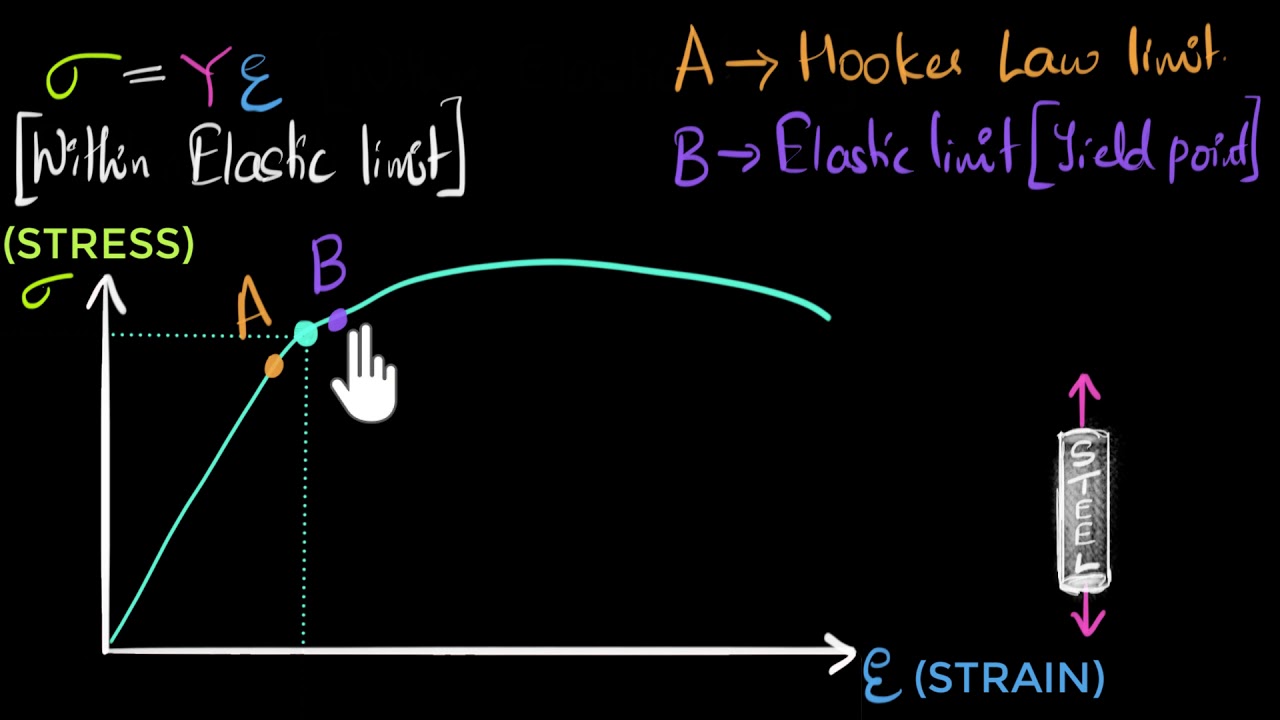

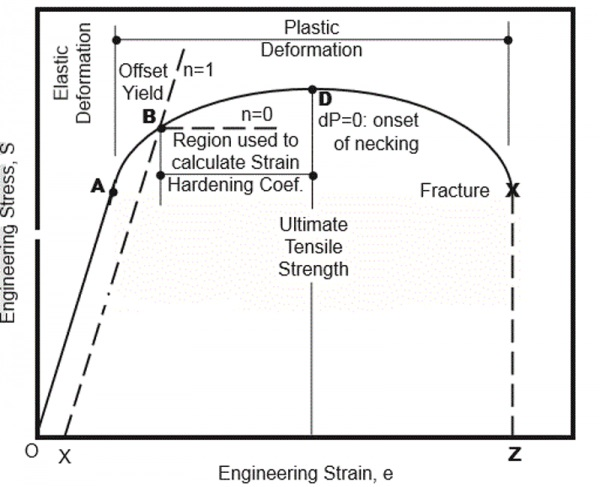

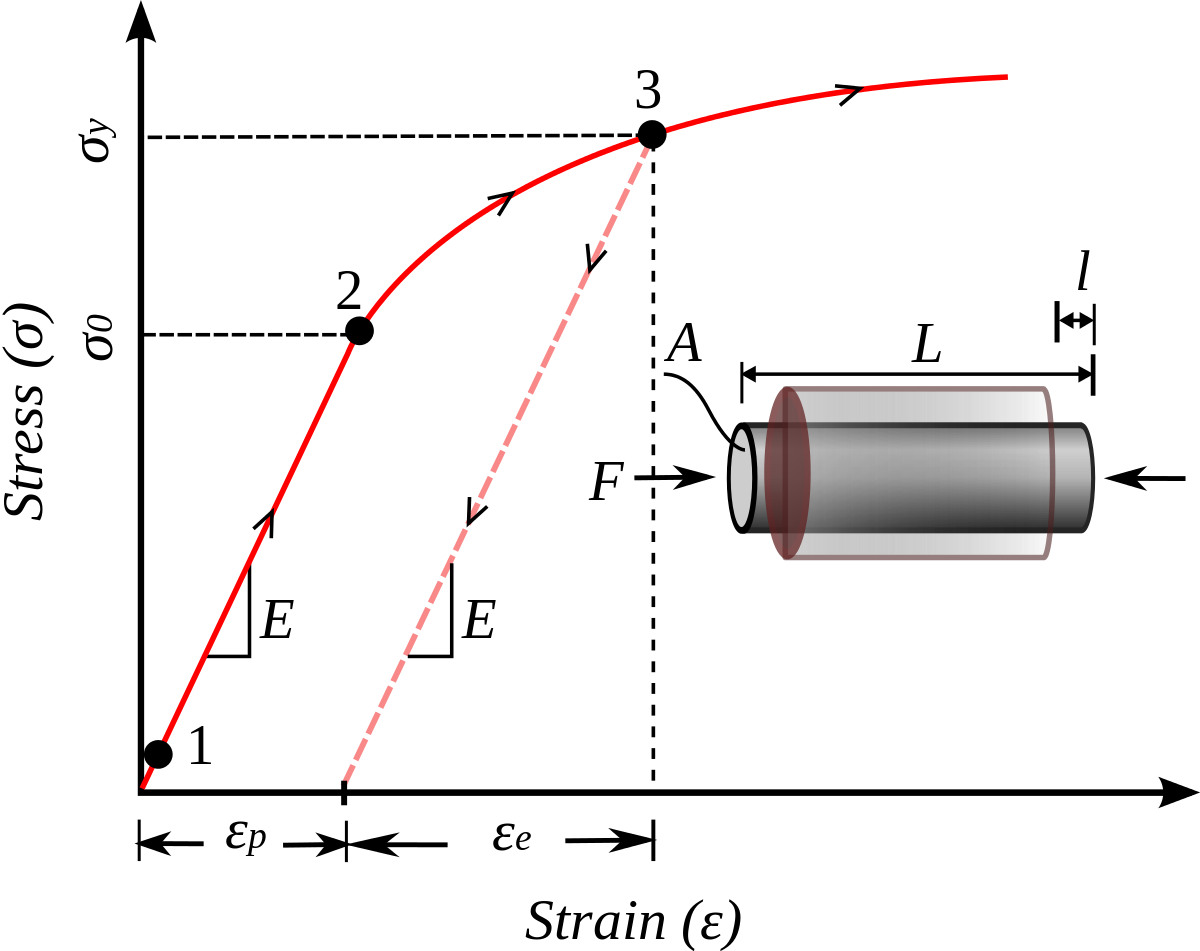

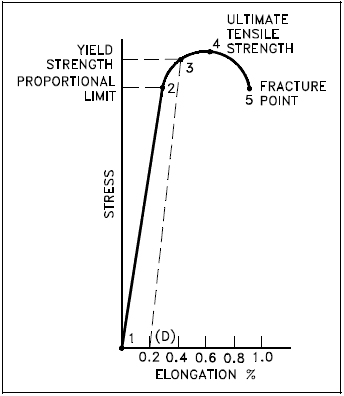

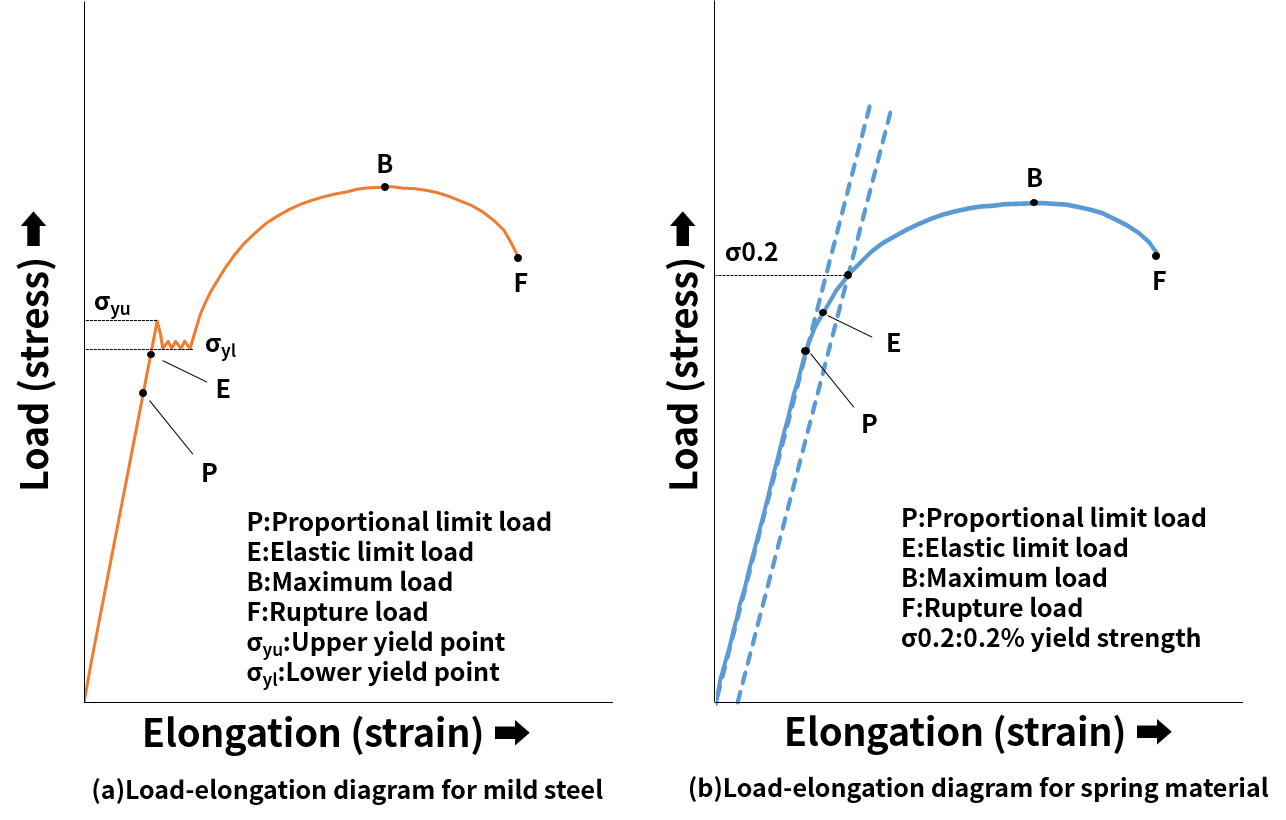

The elastic limit for steel is for all practical purposes the same as its proportional limit See accompanying figure at (1, 2) Yield point is a point on the stressstrain curve at which there is a sudden increase in strain without a corresponding increase in stress Not all materials have a yield pointYield stress and strength will now be sought Yield Stress Definition Consider a typical, ductile material stress strain curve as shown in Fig 1 Fig 1 Stress strain curve The related constitutive form will be taken to be that of the strain hardening type and applicable to any standard test such as those forCreep The time dependent deformation due to heavy load over time is known as creep In general both stress and temperature influence on the rate of creep

Engineering Stress Strain Curve

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

The minimum yield strength is the key property of steel used in pipeline design See Figure 1110This figure shows the relationship between stress and strain The minimum yield strength is defined as the tensile stress required to produce a total elongation of 05%Max = maximum beam deflection = yield strain (no units) = resistance factor = diameter symbol = resistance factor for bending for LRFD = resistance factor for compression for LRFD = resistance factor for tension for LRFD = resistance factor for shear for LRFD = load factor in LRFD design π = pi ( radians or 180 °) = slope of the beam deflection curve = radial distance Ω = safety factor for ASD = symbol for integration = summation symbolTensile / yield strengths and ductilities for some of the plain carbon and low alloy steels are given in the following mechanical properties of steel chart Yield Strength, Tensile Strength and Ductility Values for Steels at Room Temperature

.jpg)

Yield Stress Calculation Methods

Reinforcing Steel Properties Of Shear Panels Fy Yield Strength P Download Table

Yield strength When subjected to stress, a material undergoes recoverable deformation The yield strength of a material represents the stress beyond which its deformation is plastic Any deformation that occurs as a result of stress higher than the yield strength is permanentMaterial Carbon Steel, Yield Strength= psi, Modulus of Elasticity=30E6 psi, Poisson's Ratio=29, Brunell Hardness 179 Max Bending Stress o V H W t = 3068 lbf o K o = 125 Overload Factor, based on light shocks encountered o K v = 115 Dynamic Factor, based on quality and velocity of gears o K s = 1 Size Factor o PSy = yield strength (psi, MPa) t = wall thickness (in, mm) do = outside diameter (in, mm) Note!

What Is The Formula For Tensile Strength How Is This Determined Quora

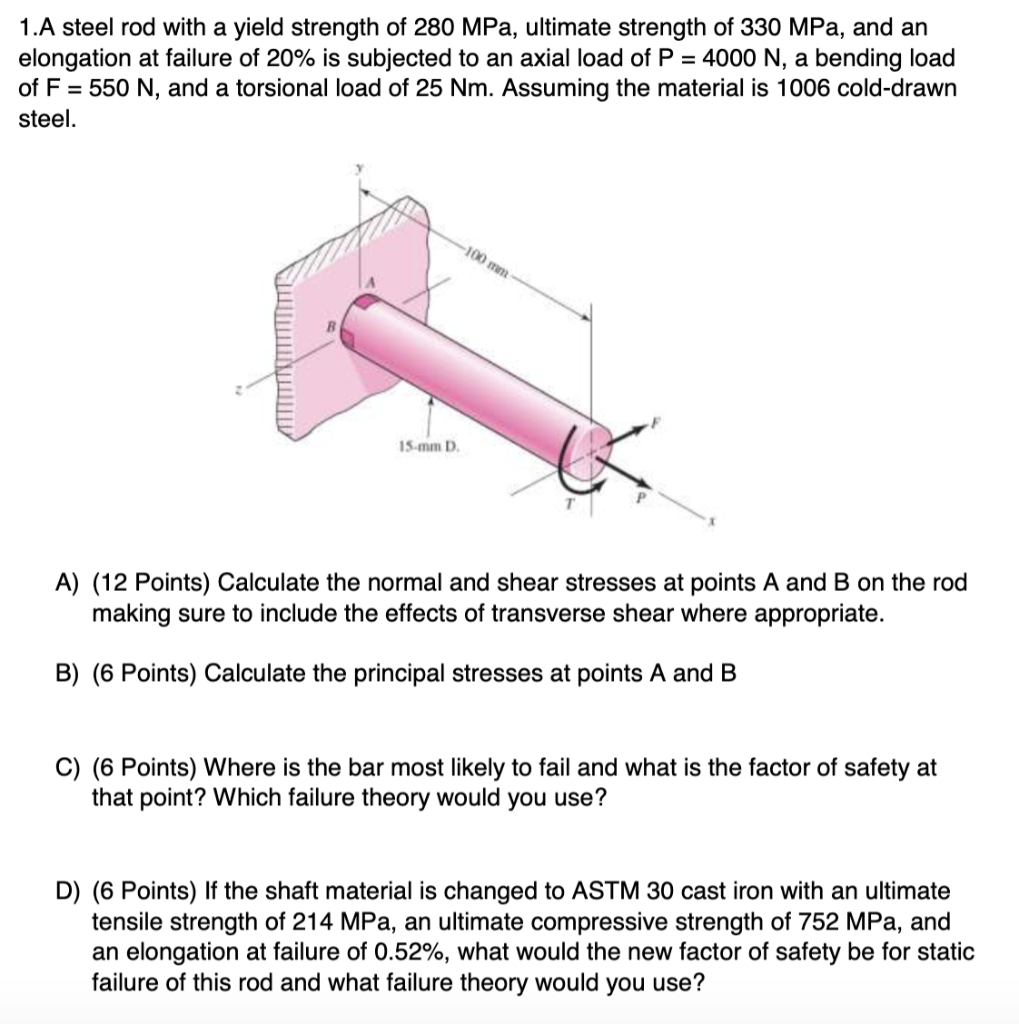

Solved 1 A Steel Rod With A Yield Strength Of 280 Mpa Ul Chegg Com

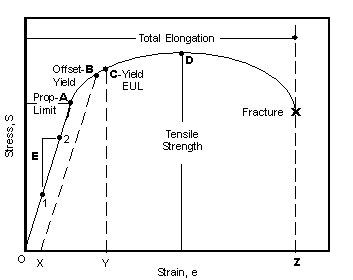

The yield strength at 02% offset is determined by finding the intersection of the stressstrain curve with a line parallel to the initial slope of the curve and which intercepts the abscissa at 02%B = width of stress block f y = steel yield strength A s = area of steel reinforcement d = effective depth of section (depth to na of reinforcement) With C=T, Asfy = 085 f´cba so a can be determined with f b A f a c s y c 085 Criteria for Beam Design For flexure designYield strength is the maximum stress that can be applied before it begins to change shape permanently This is an approximation of the elastic limit of the steel If stress is added to the metal but does not reach the yield point, it will return to its original shape after the stress is removed

Calculation Methods Of Yield Strength And Ultimate Tensile Strength By Download Scientific Diagram

Stress Strain

The formula for steel beam sizing or steel beam design is section modulus (S) = moment (M)/allowable yield stress (Fy) or in short S=M/Fy The tables for structural steel sizes such as steel i beam sizes show the steel beam dimension for a steel i beam where S can be selected to satisfy the designIn codes like ASME 13 modified versions of the Barlow's formula like the Boardman formula and the Lame formula are used to calculate burst and allowable pressures and minimum wall thicknessStress Stress is the ratio of applied force F to a cross section areadefined as "force per unit area" tensile stress stress that tends to stretch or lengthen the material acts normal to the stressed area;

Virtual Labs

Metal Mechanical Properties Chart Shear Strength Tensile Strength Yield Strength Machinemfg

The yield stress is taken to be the peak value of the elastic stress, and the corresponding strain value the yield strain It is important to note that test frequency can influence the measured yield stress based on the relaxation behavior of the material under testSimilarities and differences between yield strength and ultimate strength of solid materials are given here in table form Yield strength is maximum stress that a solid can withstand when it deforms elastically Ultimate strength indicates maximum stress withstanding capability of a solid when it deforms plasticallyYield Strength Definition Stress Strain Graph Stress Strain Graph Explanation Yield Strength Graph What is Yield Strength?

Shear Yield Strength An Overview Sciencedirect Topics

Yield Strength

Shearing stress stress that tends to shear the material acts in1) low/mild strength that is mild steel having yield strength is Fe250 which can rasist the force of stress of 250N/mm2 when applied on it tensile strength of mild steel is 410 mpa 2) high yield strength that is reinforcement Steel used in building construction for example Fe415 and Fe500 that can rasist the force of stress of 415N/mm2 andThe yield strength at 02% offset is determined by finding the intersection of the stressstrain curve with a line parallel to the initial slope of the curve and which intercepts the abscissa at 02%

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Estimating Tensile Strength From Yield Or 0 2 Proof Values Twi

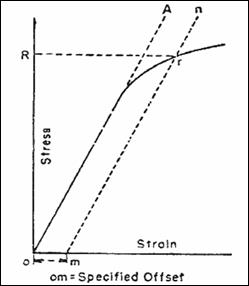

The yield point happens after an object has reached its yield stress This example is of steel Steel materials have a yield point, which causes them to have a large horizontal portion of the graphThen on the stressstrain diagram, lay off om equal to the specified value of the offset (ie yield strength ~02%), draw mn parallel to OA, and thus locate r, the intersection of mn with the stressstrain curve corresponding to load R, which is the yield strength load In recording values of yield strength obtained by this method, the valueThe general formula for bending or normal stress on the section is given by Given a particular beam section, it is obvious to see that the bending stress will be maximized by the distance from the neutral axis (y) Thus, the maximum bending stress will occur either at the TOP or the BOTTOM of the beam section depending on which distance is larger

Stress Strain Curve For Steel And Resulting Points Of Interest Youtube

.jpg)

Yield Stress Calculation Methods

1 MPa = 10 6 Pa = 1 N/mm 2 = 1450 psi (lbf/in 2);The moment formula will be M = PL/4 The allowable yield stress per code is 66 percent of yield stress which is 66x50 for 50 ksi steel for wide flange sections If you are estimating the capacity of older steel or steel where yield stress is not known, use Fy = 36 ksiYield stress Mu = maximum moment from factored loads for LRFD beam design My = internal bending moment when the extreme fibers in a cross section reach the yield stress n = number of bolts na = shorthand for neutral axis N = bearing length on a wide flange steel section = bearing type connection with threads included in shear plane

How To Find Yield Strain Corresponding To 0 2 Offset Yield Stress

Q Tbn And9gcrdlwvzddnehsqd3q4pa68yhsrtz2zujhc4jj P3hg9jteevyia Usqp Cau

Alloys like steel, which are created by feeding iron various species of impurities, are the best examples of such manipulation Another way to achieve a greater yield stress is to manipulate the material at lower temperatures Higher temperatures add to the stress, as thermal energy causes the atoms to vigorously jiggle and displaceAs yield strength is related to deformation which is a result of applied stress, the SI unit of yield strength is Nm2 In CGS system, the yield strength is gcm 2 State if the given statement is true or false In drawing deep operations of sheet steels, problems are created by yield point phenomenonFigure 4 shows the flow stress curves for a drawquality steel (AKDQ), an aluminum alloy (Al 5754), and a highstrength steel (DP600) Force and elongation are the measured values (Figure 1), while the engineering stressstrain curves (Figure 2) and flow stress curves (Figure 3) are calculated using the previous equations

Solved A Ductile Hot Rolled Steel Bar Has A Minimum Yield Chegg Com

What Is The Difference Between Upper Yield Point And Lower Yield Point Of A Stress Strain Curve For Mild Steel Quora

The stress value, in pounds per square inch, is the yield strength It is indicated in Figure 5 as Point 3 This method of plotting is done for the purpose of subtracting the elastic strain from the total strain, leaving the predetermined "permanent offset" as a remainderOf these, the yield/stress ultimate tensile stress (Y/T) ratio limits are particularly restrictiveThen on the stressstrain diagram, lay off om equal to the specified value of the offset (ie yield strength ~02%), draw mn parallel to OA, and thus locate r, the intersection of mn with the stressstrain curve corresponding to load R, which is the yield strength load In recording values of yield strength obtained by this method, the value

Finding 0 2 Offset Strain Dplot

Isbt212 04 3 Stress And Strain Proportional Limit And Yield Strength Youtube

Whether an object is stubborn or malleable is decided by the yield strength It is the point at which an object ceases to be elastic and becomes plastic Yield strength helps us choose appropriate materials for the construction based on the requirementYP ⇒ Yield Point Stress at which there are large increases in strain with little or no increase in stress Among common structural materials, only steel exhibits this type of response σ YS ⇒ Yield Strength The maximum stress that can be applied without exceeding a specified value of permanent strain (typically 2% = 002 in/in)Yield strength is the maximum stress that can be applied before it begins to change shape permanently This is an approximation of the elastic limit of the steel If stress is added to the metal but does not reach the yield point, it will return to its original shape after the stress is removed

Solved Problem 1 Find The Ultimate Tensile Strength An Chegg Com

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Tesile Property Of Pipe Drilling Formulas And Drilling Calculations

Stress Strain Diagrams Youtube

What Is A Proof Stress Definition From Corrosionpedia

What Is 0 2 Of Offset Method In Yield Strength Quora

Q Tbn And9gcsubgeg9vwumror Qhoghyyxdjrgpugf4zei Gvjvgk9mt175y Usqp Cau

Solved A Ductile Hot Rolled Steel Bar Has A Minimum Yield Chegg Com

Yield Strength

How To Find Yield Strength Quora

Solved Problem 1 Find The Ultimate Tensile Strength An Chegg Com

A36 Steel A Tensile Strength Calculation For Reference Not Corroded Download Scientific Diagram

Reduction Factors For Stress Strain Curves Of Steel At Elevated Download Table

Q Tbn And9gcrf0yb4daxmcs4hece0wbtm Gkjp Dgiun5uwt1stzt02mpf2vo Usqp Cau

Stress Vs Strain Curve Video Khan Academy

How To Find Yield Strength Quora

Which Methods To Use For Sheet Metal Tension Testing

Yield Engineering Wikipedia

Bending Of Rails In The Reinhardt Cremation Facilities Yield Strength Analysis Holocaust History Channel

Failure Strength Sf From Re Rm R 0 2 E And Efailure

Tensile Strength Of Steel Vs Yield Strength Of Steel Clifton Steel

Tensile Strength Of Steel Vs Yield Strength Of Steel Clifton Steel

Yield Strength Strength Mechanics Of Materials Engineers Edge

Yield Strength Strength Mechanics Of Materials Engineers Edge

113 Questions With Answers In Yield Strength Science Topic

Yield Strength

Civl 1101

Correlation Between Engineering Stress Strain And True Stress Strain Curve

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Yield Strength Definition Examples Stress Strain Graph Faqs

On Cyclic Yield Strength In Definition Of Limits For Characterisation Of Fatigue And Creep Behaviour

Stress Strain Curve An Overview Sciencedirect Topics

On The Gradient Of The Yield Plateau In Structural Carbon Steels Sciencedirect

Lower Yield Point An Overview Sciencedirect Topics

Minimum Yield Strength An Overview Sciencedirect Topics

What Is The Difference Between Ultimate Stress And Yield Stress Quora

Stress Strain Curve Wikipedia

Solved A Ductile Hot Rolled Steel Bar Has A Minimum Yield Chegg Com

Work Hardening Wikipedia

Engarc L Offset Yield Method

Finding 0 2 Offset Strain Dplot

Yield Strength Definition Examples Stress Strain Graph Faqs

Machinning And Materials The Blog From A Lean Thinker

Yield Strength Definition Examples Stress Strain Graph Faqs

Strength Of Materials Basics And Equations Mechanics Of Materials Engineers Edge

To Determine Yield Strength Tensile Strength Of A Steel Bar By Offset Secant Method

Www Aisc Org Globalassets Aisc Manual 15th Ed Ref List Specification For The Design Of Steel Hollow Structural Sections Pdf

Problem With Cantilever Beam And Yield Strength Engineering Stack Exchange

Calculate Yield Stress Youtube

Yield Strength Yield Point Stress Strain Curve

Properties Of Metals Engineering Library

The Uniaxial Yield Stress For A Steel Material Is Chegg Com

A Note On Parameter Identification Of The Aisi 304 Stainless Steel Using Micromechanical Based Phenomenological Approaches

Astm E8 Measuring The Tensile Strength Of Metals

Material Properties

Q Tbn And9gcsrdl8wwvejgxetlbntwved Q8j9af6bhbb1ktdahvmnxvkfkq8 Usqp Cau

Temperature And Strength Of Metals

Yield Point Instron

Yield And Tensile Strength Engineering Materials Youtube

Yield Stress Sy Of Different Sized Single Crystal Iron Samples Range Download Scientific Diagram

Flexural Behavior Of Beams Reinforced With Steel Bars Exceeding The Nominal Yield Strength

Calculation Methods Of Yield Strength And Ultimate Tensile Strength By Download Scientific Diagram

The Differences Between Stiffness And Strength In Metal

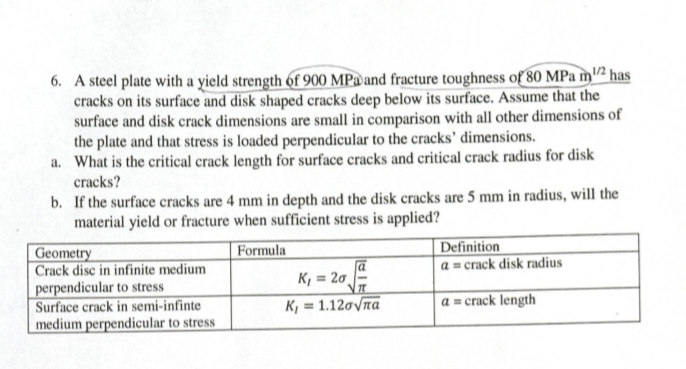

1 2 As 6 A Steel Plate With A Yield Strength Of 9 Chegg Com

Compression Springs How To Calculate Spring Stress Tokai Spring Industries Inc

Importance Of Yield Strength Plastic Deformation To Civil Engineers

How To Measure Tensile Strength Elastic Modulus And Ductility Rolled Alloys Inc

Exploring The Stress Strain Curve For Mild Steel The Chicago Curve

A Comparative Evaluation Of Metallurgical Properties Of Stainless Steel And Tma Archwires With Timolium And Titanium Niobium Archwires An In Vitro Study Vijayalakshmi R D Nagachandran K S Kummi P Jayakumar

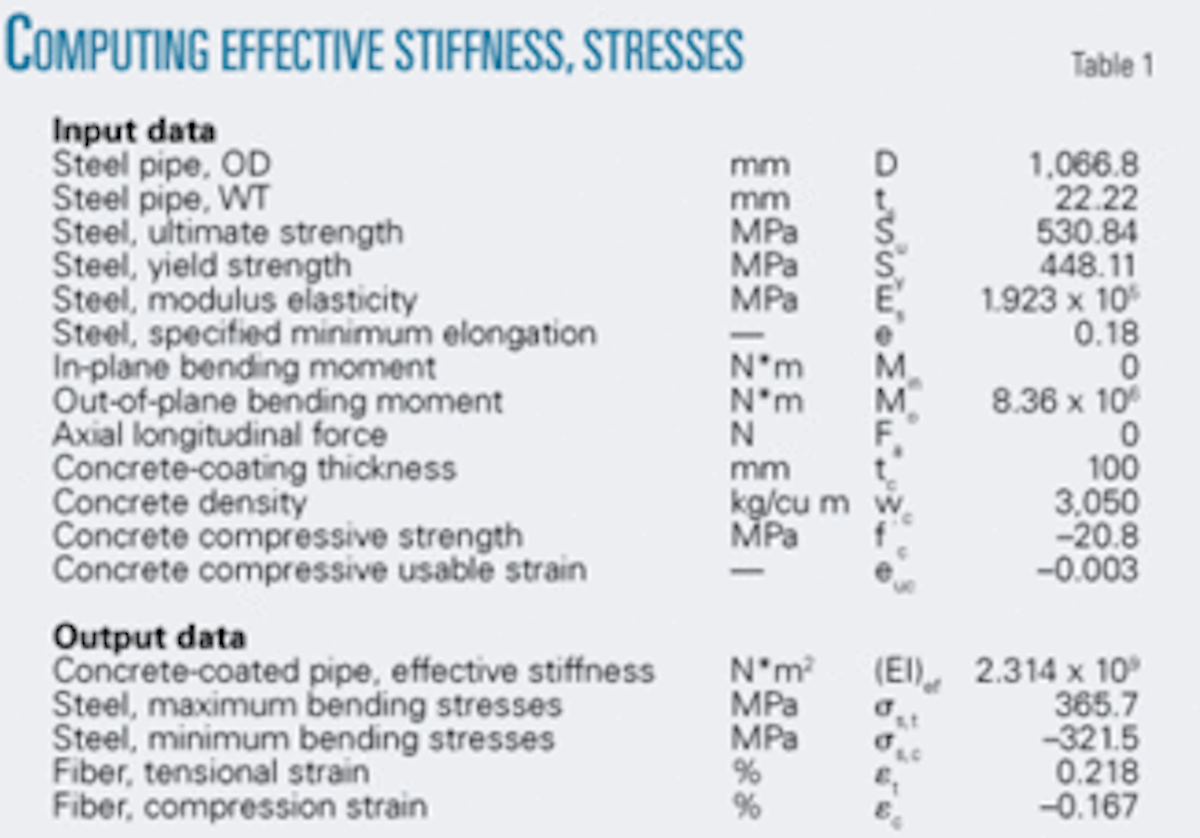

New Method Sets Concrete Coating S Effect On Pipeline Stiffness Stress Oil Gas Journal

Why Your Nds Nail Calcs Could Be Wrong And What You Can Do About It Simpson Strong Tie Structural Engineering Blog

What Is The Difference Between Upper Yield Point And Lower Yield Point Of A Stress Strain Curve For Mild Steel Quora

コメント

コメントを投稿